Why Axes Have Curved Blades – Illustrated

Axes almost always have a curved blade. Some have big sweeping blades while others are nearly straight. I never really thought about it until I started restoring axes, re-profiling heads, and sharpening edges.

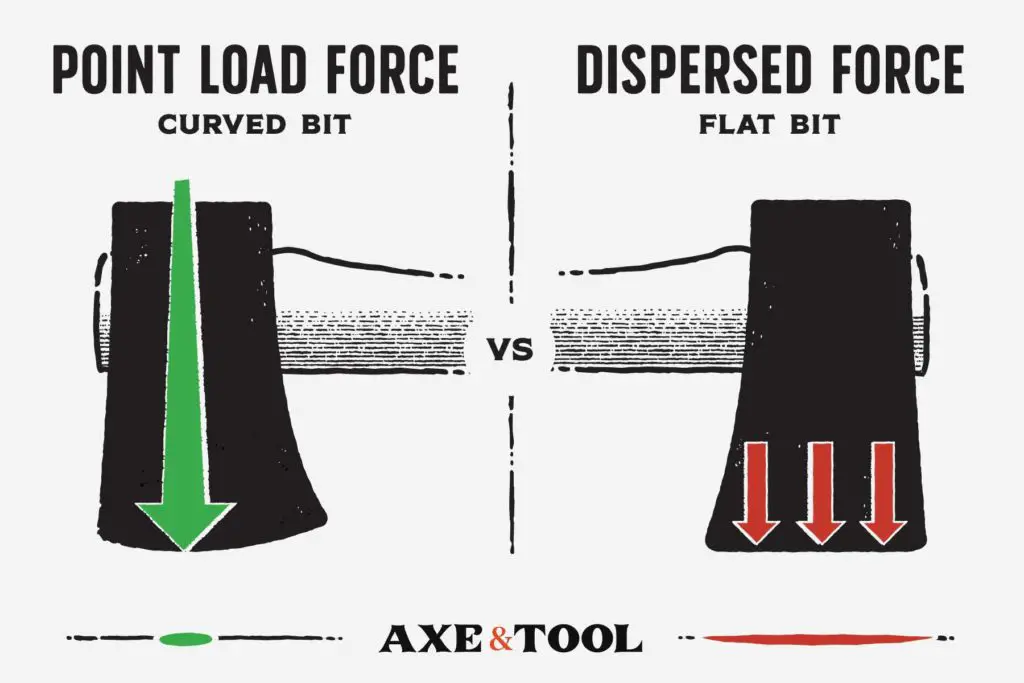

The bit (blade) of an axe is curved primarily to cut deeper. The force of the swing is concentrated into the small point on the blade that makes first contact with the wood, driving it deeper. This is called point loading. A curve also makes the cutting edge longer and lets an axe rock-free if stuck.

A curve is the strongest and easiest way to create a “point” to transfer the concentrated energy of the swing. That point will drive deeper pulling the rest of the blade with it.

The nice thing about a curved blade is that any spot can be the “point” of contact.

So even a poor and off-center swing will be (more) effective with a curved blade, than with a flat one. And when your chop connects on the lower end of the blade first, the momentum will actually roll your axe forward creating a larger cut.

But not all axes are curved the same.

Can an axe blade be too curved?

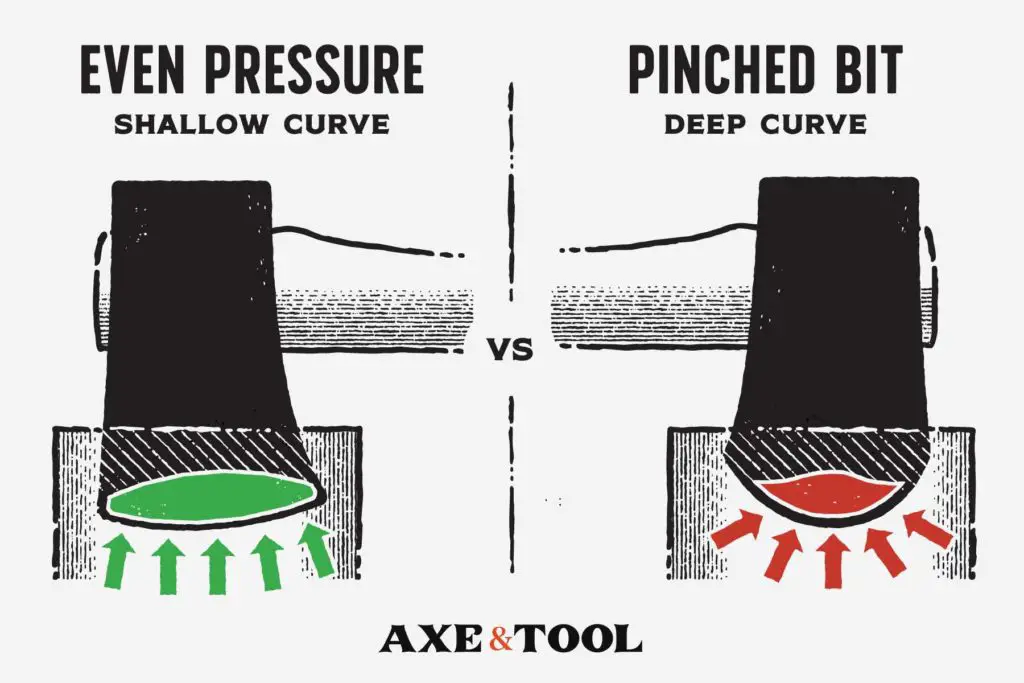

An axe with too deep a curve is usable but less efficient and more likely to get stuck than an axe with a properly curved bit.

- It will require more swings to make up for the inconsistent cutting depth.

- The axe can get stuck easier. Without the full width of the blade to disperse the pressure, the extended blade can be pinched.

A rounded or unevenly curved bit is often found with old axes that have seen a lot of use. The heel and toe of an axe head can take a lot of abuse if an axe is used roughly. Repeatedly get chipped on things like rocks and then ground down and resharpened only where the damage was.

The toe and heel of an axe bit (the corners) also help give leverage to rock a stuck axe free, but if the curve is too deep you will lose that leverage point. Making it get stuck easier and also harder to get free.

Too curved a bit will also be more fragile. You can chip or knick the sides of the protruding bit, which can jeopardize the whole blade. A subtle curve will be more supported and only be damaged on the front.

Unfortunately, you often can’t fix this on an old axe. If you file back the edge too much you will take decades off the life of the axe, or sharpen out of the tempered area. You CAN still use an old axe even if the blade is “too curved”.

How curved should it be?

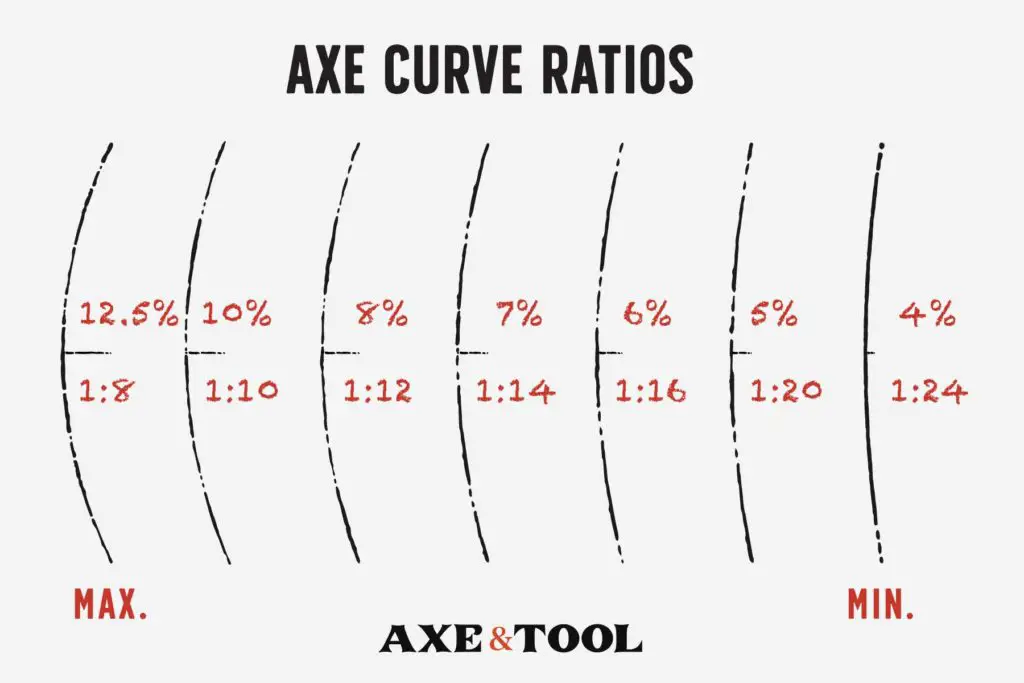

I traced and measured 50+ axes to figure out what an acceptable curve is. I used different patterns and sizes from American, Canadian, European, and Swedish manufacturers.

Drawing a straight line from the heel to the toe, I measured the length of the cutting edge and then the depth of the curve from that line.

Here’s what I found:

Depth of curve for axe blades

| Edge length | Max. Curve | Average | Min. Curve |

| 3.0” | 0.375 | 0.25 | 0.15” |

| 3.5” | 0.4375 | 0.30 | 0.18 |

| 4.0” | 0.5 | 0.35 | 0.20 |

| 4.5” | 0.5625 | 0.4 | 0.23 |

| 5.0” | 0.625 | 0.45 | 0.25 |

| 5.5” | 0.6875 | 0.5 | 0.28 |

With these measurements, I found consistent ratios of curve depth : blade length. The range of curve depth is between 1:24 to 1:8, but most of the axes I tested (75%) fell within a narrower range of 1:20 to 1:12.

The classic resource The AX Book by Dudly Cook recommends a ¼” curve on a 4.75” bit to be the “perfect” shape for an axe. This is right around the 5% or 1:20 mark.

How axe use is impacted by the curve of the blade

There are a few common bit shapes that can be found across many head patterns, but note curve alone does not dictate the purpose of an axe, it’s just one of many attributes.

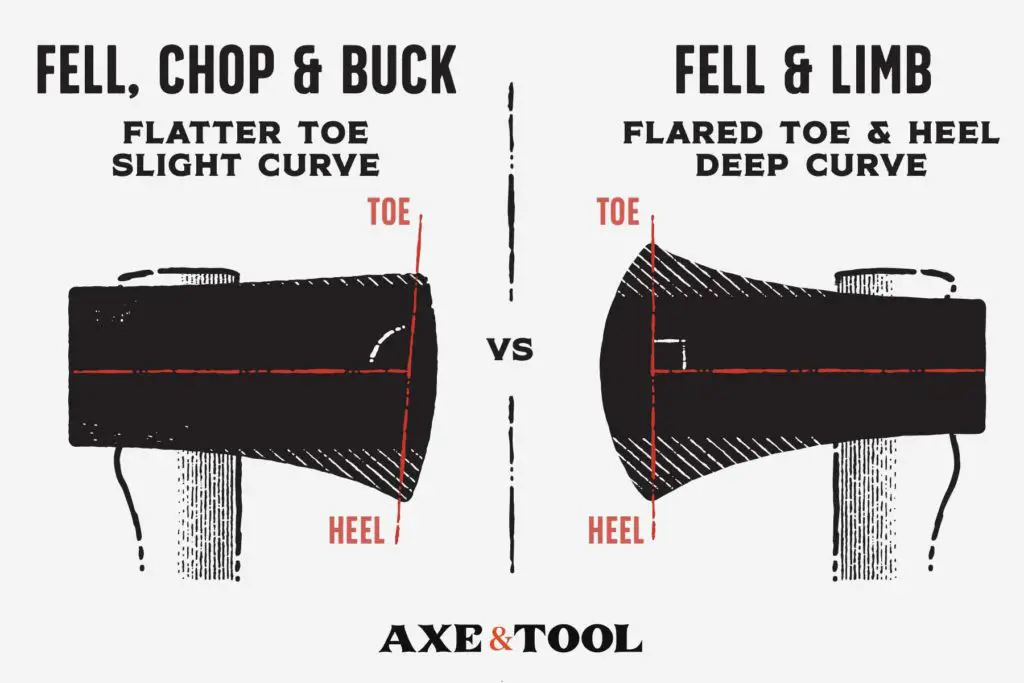

Shallow top forward curves are best for felling and chopping

A common blade shape for a felling or chopping axe will have a shallower curve, with the heel (bottom) of the bit angled back towards the handle. This is a common North American blade shape.

The shallow curve is less likely to get stuck and provides more even cuts.

The angle of the bit allows for easier bucking since you can connect with the toe on downstrokes, and deeper wider cuts feeling by connecting with the heel first and having the momentum carry the axe forward.

This pattern also works as a splitting axe.

Deep flared curves are best for felling and limbing

Patterns like Rhineland, Hoosier, and Swamping double-bit axes axe with wide and flared bits tend to be better for limbing than chopping. The flared toe and heel combined with a deep curve creates a longer cutting edge that can catch branches and continue to cut them as they drag across the blade. There is usually no angle to the bit, so the apex of the curve is in the middle, perpendicular to the handle.

The deeper curve also makes for better penetration, so they are more likely to cut into branches that are unsupported and will cut deep when felling.

They are not as suited for chopping on the ground – especially bucking. as the flared toe and heal are much more likely to end up in the dirt, and it’s more difficult to land hits at different angles.

These flared heads are not ideal for splitting.

Splitting axes

Dedicated splitting axes tend to have short very shallow curved blades, sometimes practically straight. These axes tend to be heavier and rely on a flared head shape not a deep cutting bit to force the wood apart.

Specialty axes:

Of course, some specialty tools like carving axes may break all these rules by having deeply curved bits with the apex at the bottom and upward hang. However, this is specifically done for fine carving work achieved by motions from the hand, wrist, and forearm, rather than an axe swing.

Why do some axes have straight blades?

Okay so we just covered why curved bits are better in every way – so why are there still axes with straight cutting edges?

Carpenters axes:

The flat edge is used for more detailed shaping where you might want to create a flat surface. You aren’t trying to cut through a log, but shape and square logs or notches.

Roofing axes:

These hatchets act more like a small splitter and are used to quickly break old shingles apart.

Throwing axes:

The straight edge is better for throwing because it is less likely to roll out of the target. The corners become the loaded point and drive into the wood.

Summary

The curve of an axe bit can greatly impact the performance of your axe, but the curve alone does not dictate the purpose of an axe, it’s just one of many attributes.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Very good Jim, I have enjoyed reading your website. I’m no expert. Your info is presented clearly and in a way that makes understanding very easy. ~ Dick

Appreciate the kind words!

Thank you Jim,

A fab resource, much appreciated.

D

Thanks, glad you found it useful!