How Thick Should An Axe Handle Be? Answered.

There’s a lot of talk online about “thinned” axe handles – but what does that mean? How thick should they be?

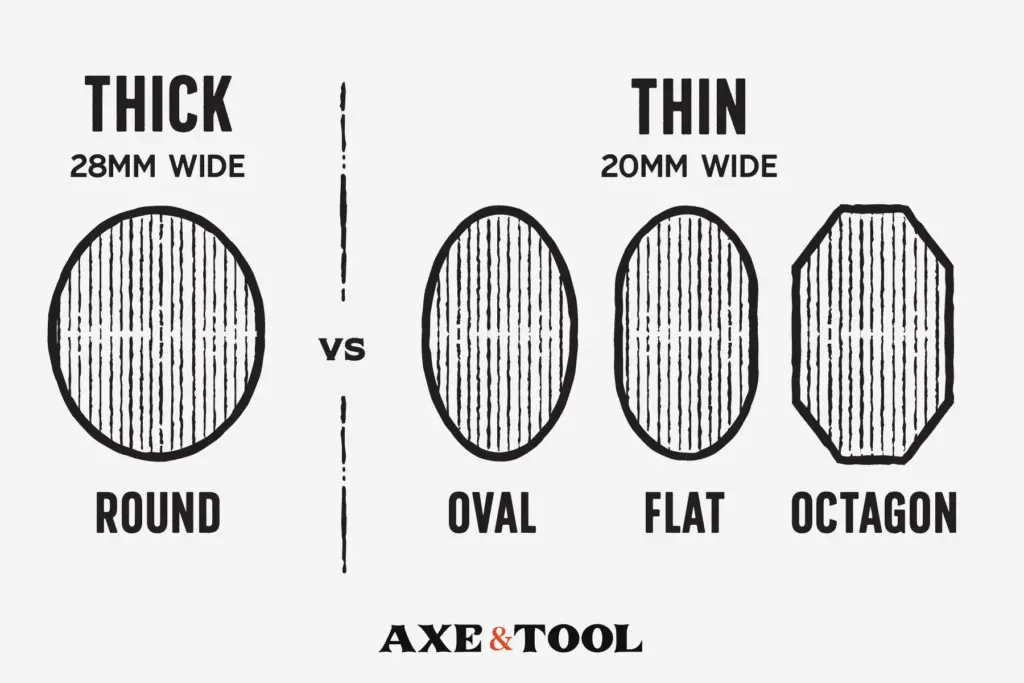

Traditionally an axe handle should be between 18-21mm or 0.7″-0.825″ thick. Modern axe handles tend to come thicker (between 23-28mm). Thin handles flex to absorb shock and are more controllable but can have drawbacks for inexperienced users.

This width range is ideal for both boy’s axes (28″) and full-size axes (36″), but it can be a little wider or slimmer depending on your preference. I have a few axes with original handles from the “golden age” (1920-1940), and they are all between 18-21mm. Even the 36” handle with a large 4lb head is 19mm (0.75in).

19mm (0.75″) is often sighted as a good target for thinned handles. It’s referenced in “The Ax Book” by Dudly Cook, as well some of the more prominent YouTubers like SkillCult.

I have found most of the handles I have thinned myself ended up 21mm / 0.825″ (without measuring at the time). It’s a good width for a “general purpose” axe.

There are three typical profiles of a thinned handle – oval, flat-sided, and octagonal. What shape you want is totally a matter of preference.

Most axes and handles come far too thick today, and likely need to be thinned. However, there are reasons you might not want to thin an axe handle – and I will get into that further on.

If you want to know more, I have an article with multiple ways for how to thin your handle.

What about from front to back?

The handle depth (front to back) should be about 35mm, although again there is a range from about 33mm to 37mm.

You want a thin handle and a fat palm swell

This is a matter of preference, but a larger palm swell will lock your hands into the handle and reduce slipping. A couple of my nice axes with really thin handles still have palm swells that measure 38mm / 1.5″ across at the bottom, which is double the handle width.

How thick are modern axe handles?

I tested about 20 modern axes, there were only two that fall in the ideal range (one of which was $$$) and only a few more that come close. A few mm or fractions of an inch doesn’t sound like much, but the more chopping you do the more amplified it becomes.

| Model | Length | Width (mm) | Width (in) |

| Lamaca Light Forest Axe | 23” | 20mm | .8″ |

| Council Tool Flying Fox | 16” | 21mm | .82″ |

| Hults Bruk Anaby | 20” | 23mm | .9″ |

| Hultafors Ekelund | 20” | 23mm | .9″ |

| Hults Bruk Jonaker | 9.5” | 23mm | .9″ |

| Hultafors Ågelsjön | 9.5” | 23mm | .9″ |

| Gransfors Bruk | 19” | 23mm | .9″ |

| Council Tool Boys Axe | 28” | 23mm | .9″ |

| Council Tool WoodCraft | 19” | 24mm | .94″ |

| Ochsenkopf | 13” | 25mm | .98″ |

| Husqvarna | 13” | 25mm | .98″ |

| Hults Bruk Standard | 20” | 25mm | .98″ |

| Hultafors Standard | 20” | 25mm | .98″ |

| Agdor Splitter | 20″ | 25mm | .98″ |

| Garant | 26” | 25mm | .98″ |

| Husqvarna | 26” | 26mm | 1″ |

| Hultafors Standard | 28/36” | 26mm | 1″ |

| Agdor | 28/32” | 26mm | 1″ |

| Yardworks | 24”/36” | 26mm | 1″ |

| Cold Steel Trail Boss | 28” | 28mm | 1.1″ |

If you only use your axe occasionally, this is not really a big deal. Spending a little bit of time chopping with a fat handle will be fine, even if it’s not ideal. But if you are planning on working with your axe a lot you should pay attention to your handle shape.

Note: I still give a pass to the Hults Bruk and Gransfors handles for the small axes. While they are a little fat for felling, the extra width gives a little more strength for prying, which can come in handy for bushcraft work. See more below on when NOT to thin an axe handle.

Why are thin axe handles better?

Having a thin handle is not just a “comfort” thing. It can reduce vibration, fatigue, chances of injury, and improve efficiency overall. It’s no joke.

1. Thin axe handles bend to reduce vibration

An axe handle needs to flex to work properly. The handle bends on impact, absorbing the force and reducing the felt vibrations. If the handle is too thick it won’t bend, and all the force of the impact will go straight into your arms.

2. Thin handles reduce fatigue

A thick round handle needs to be gripped tightly to keep it steady and stop it from rolling in hand. The tighter you grip the handle the more shock and vibration will go directly into your hands and arms.

The extra grip strength and extra shock and vibration are fatiguing and will wear on you way quicker.

You can get tennis elbow using a fat-handled axe for too long.

3. Thin handles are more accurate

A thinned handle will have flatter sides making it easier to direct the axe more accurately. You get a more tactile feel for where the axe is pointing and it won’t roll in your hand.

When to not thin an axe handle

Depending on how you plan to use the axe you may want it a little thicker.

Splitting axes may need stronger handles

Thin handles are excellent for chopping, but they have a disadvantage if you need to pry from side to side. Rather than providing leverage to pop wood apart, the handle will just flex, bend, and possibly break.

So for this reason you likely want a bit of a thicker handle for a splitting axe, or even a general-purpose axe that can work in both rolls.

You can split wood with a thin handle, you just need to be a little more careful how you operate.

Like I said earlier, most of my general work axes have around a 21mm or 0.825” wide handle, which works for me.

Bushcraft axes need to be versatile

Bushcraft axes need to be relied on to perform a bunch of tasks far from home, so I am okay with a little extra thickness for strength in the handle for prying and leverage.

The handles on my 20” Hults Bruk (Hultafors) and 19” Gransfors Bruk axes are a little thicker at 23mm, and I didn’t thin them down.

21-23mm is a good range for this style axe. My primary brush axe is one I restored, it’s a 21” Sandvik (also Swedish) – and it has a handle width of 21mm, and I would not go thinner in this roll.

Why are modern axe handles so thick?

So if thin handles are better, why are most axe handles today so thick? Basically to save money.

Most axe handles come thick because they are cheaper to produce and less likely to fail. The shaping takes less time and skill, and the extra width will strengthen using lower-grade wood. Thick handles will also withstand novice axe users prying and twisting in a way that would snap a thin handle.

Lower-grade wood may be used to keep costs down, and that also means not wasting time sorting or lining up cuts. So the extra width will reduce the chance of poor grain orientation resulting in a break.

There is not a lot of money in mass-produced axes anymore, and every penny counts. Most people do not want to buy a premium axe. They just want an affordable tool they can use once or twice a year and then forget about.

There is no benefit for companies to spend the money thinning handles when the majority of users don’t know how to use or handle it properly – and don’t want one.

The benefit to a fat handle is it lowers the upfront cost to you, and you can tune it exactly to your liking. Again – if you want to know how to thin your handle you can see my guide here.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

I have see axes with a Pin thru the head and handle. Do you recommend this for All axes ? It is an obvious safety feature. Thank you

I’ve never pinned an axe – I think it’s overkill. A decent hang should be more than enough. The only axes that I know that consistently use them are racing axes. But those are big heavy heads, swinging fast and surrounded by people – so that makes sense.