3 Reasons Axes Have Notches (with pics & diagrams)

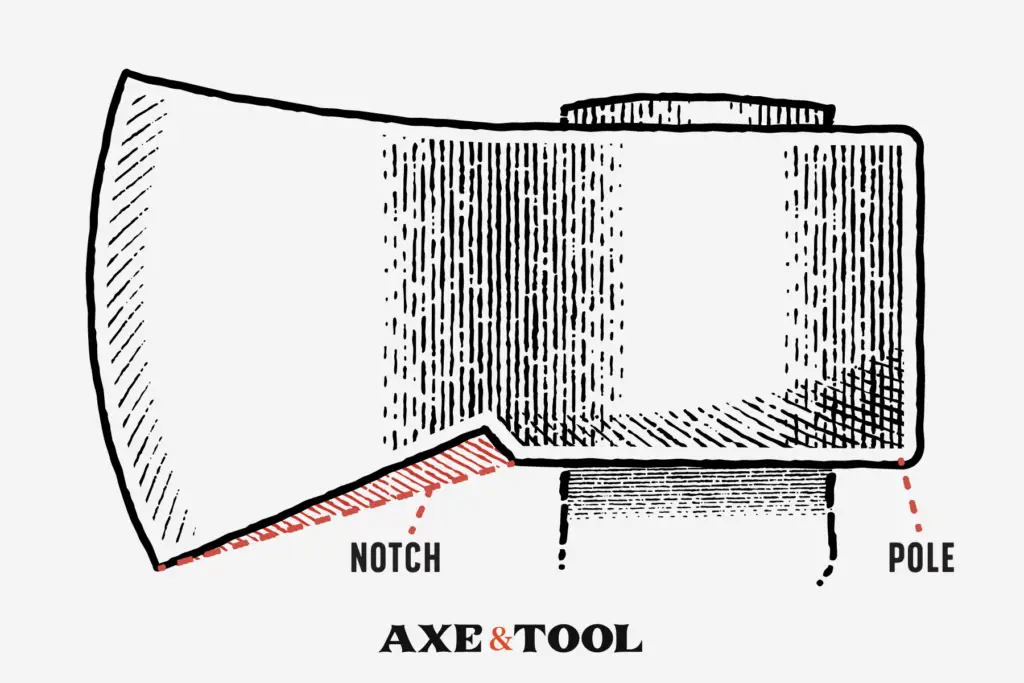

Notches can be found in many sizes and patterns of axe and hatchet. It’s not always clear why, but they usually aren’t just for show.

The big three reasons for a notch in an axe are:

1. Working with nails

2. Improving performance

3. Control and precision

1. Nail-pulling notches are common in hatchets

Let’s get the easy one out of the way.

Nail-pulling notches are often found in hatchets and are easy to identify. They will be a skinny V or U-shaped notch, typically on the bottom side of the blade.

They can be found on a “standard” hatchet as well as specialized tools for roofing and construction.

The nail puller is typically on the bottom side of the blade to give the user better leverage when prying. But they can be found on the back of the head as well.

I have seen nail pullers on the top of the axe head – but it is almost always a result of someone rehanging an old axe head upside down.

Why would a hatchet have a notch in the blade?

A deliberate notch can be found in the blade of specialized axes like lathing hatchets and barrel-making hatchets. This notch can be used to hold a nail in place while hammering or as a space for working around existing nails to avoid chipping the cutting edge when prying boards up.

These hatchets also usually have real nail pullers in the standard areas.

2. A small V notch can improve the function of an axe

A small notch on the bottom of an axe is fairly common, and it’s not just there for decoration.

This one little V-shaped notch can improve the balance of your axe, extend the life of your handle, and give you more control.

A notch can improve an axe’s balance

The small V notch can be used to lighten the blade side of the axe. This is not done to reduce the weight overall, but to improve the balance of the axe for horizontal swings.

The pole (back of the axe) sticks out to help act as a counterweight to the blade, but most axes still won’t be perfectly balanced.

If an axe is too blade-heavy, it can cause additional fatigue and strain on the user.

The blade will naturally droop down on horizontal swings, so the user will have to grip the handle extra tight to keep it on target. This means there will be a greater transfer of vibration into the user’s hands/arms, and will just be more tiring overall.

A well-balanced axe can be loosely held and almost thrown and guided into the tree.

A notch can reduce stress on an axe handle

A small V-shaped notch can disperse the force of impact away from the handle on axe patterns with larger blades and smaller eyes.

Axe patterns like Rhineland or Hudson Bay can benefit from this notch.

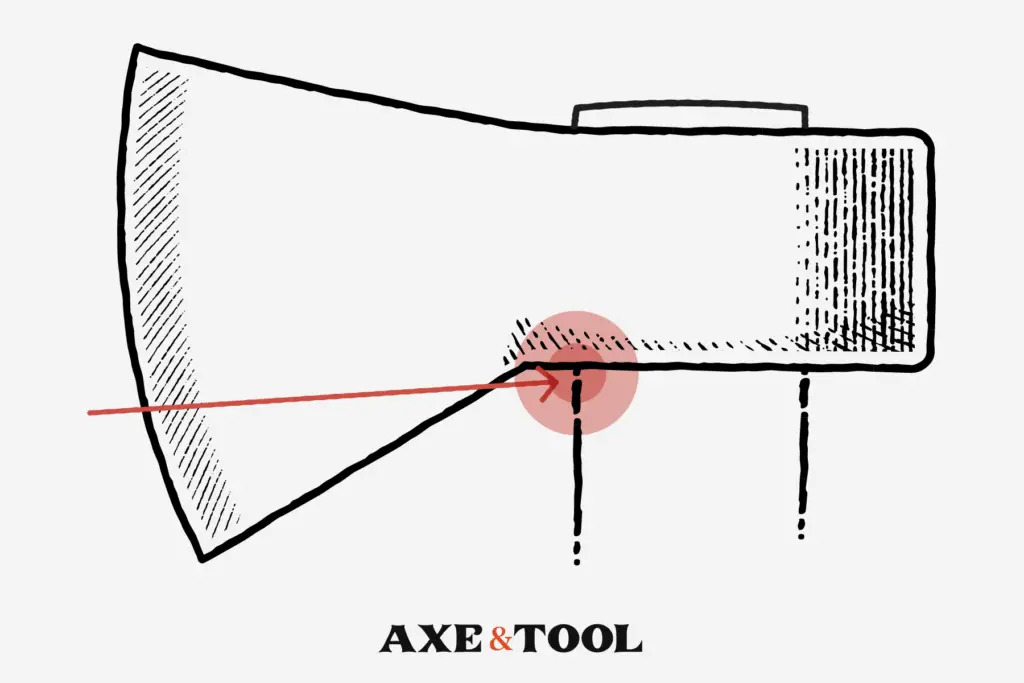

When you chop (especially with the lower portion of the bit), the force travels through the head and naturally tries to turn where the connection with the handle into a pivot point.

This isn’t a problem for many axes, but if the eye portion of the axe is small the repeated impacts can slowly push the front of the head downward. This will compress a ledge in the wooden handle over time, loosening the axe.

The notch will help, by turning the point in the notch into a first “rotational” point and moving it above the connection with the handle. This disperses and redirects the force so it’s not completely being turned into downward pressure on the handle.

I’m not sure how much it really helps, but that’s the idea in general.

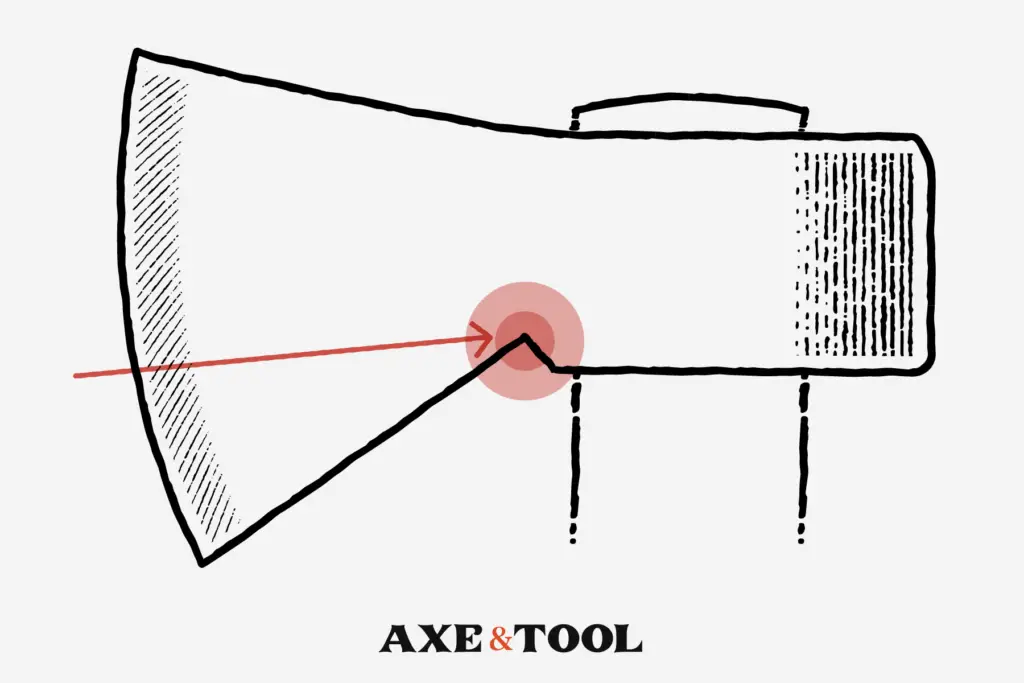

An added benefit of control

One of the first two reasons is generally why a notch like this is added, but a side benefit is fine control of the blade. The notch increases the angle coming up from the heel of the blade, which leaves more space for your hand. So it’s easier to choke up on the axe and use it one-handed for things like carving, or kindling.

However, there are some axes that very deliberately have large notches for just this purpose.

3. Large notches give detailed control of an axe

Gransfors Bruk, Hults Bruk, and Council Tool Woodcrafter are all popular axes that are favorites of bushcrafters because of their unique controllable designs. A deep notch-shaped bottom allows the user’s hand to fully get behind the blade.

Axes are easier to control for tasks like carving, or fine cutting when your hand is right behind the cutting edge. You can direct and add pressure behind the blade without rolling your wrist. You can also use your finger on the side of the head to guide fine movements.

The back of the notch drops back down to increase the amount of surface area connecting with the handle. This prevents any loosening problems while allowing the user to have more grip options.

These large notches are typically rounded and found on heads between 1 and 2 pounds. Heads larger than 2 lbs aren’t shaped this way because they start to be too heavy for fine control even with the notch.

Bearded axes take this to the extreme.

What is a bearded axe?

Think Viking axes.

The beard of an axe is when the blade drops and extends down, leaving a gap between it and the handle. This axe here has a small beard (I don’t own any of the Viking styles).

The beard is also a feature that gives the user more control but with the added benefit of a much larger cutting edge. These axes can be very versatile, with interesting blade shapes that can be used for many tasks.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Thank you for the lesson. I just had my grandfather’s hatchet cleaned and sharpened for the first time in probably 60 years and wondered about it.

Quite interesting read. I have about 20 Montreal and Hudson Bay Pattern axes most of them made by Gransfors Bruk and Hults Bruks. I also have a few Walters Tomahawk. I have a Berghaus Sweden marked axe which I read somewhere it was made by Welland Vale. These Montreal Pattern axes have different notches. GBs and HBs notches look like they were ground off while Walters notches were hammered and ground. I have a few unmarked axes which have the notches formed by forging mold dies. The Berghaus axe is one of them and I wonder if the unmarked ones also made by Welland Vale. I also see many unmarked Hudson Bay axes on ebay as Snow and Nealley. Any thoughts on this? Thanks from Vancouver.

Thanks for writing, sounds like you have a great collection. I am by no means an expert, but I have a few ideas:

1. I don’t think Berghaus were made by Welland Vale (I have one as well), I think they are Swedish. Likely under contract by GB or HB. I found this snippet about the company (see here)

2. The “right” way to form the notch is when forging, but my hunch is that notches that were ground were as a cost cutting measure. It’s probably easier to teach someone to grind a notch than spend the time shaping the head. Especially from the 50’s on when the axe industry was declining.

3. Not sure about the HBs on ebay. Snow & Neally (if that’s what they are), were US made but have now been made oversees for a while – so who knows.

No certain answers, but some ideas (from Ontario)

Good site. Thanks for the information.

Thanks!

Hello, I enjoy bush craft and restoring axe bits that I find in antique shops. Your article is interesting and helpful whith the different kinds of axe I find at the stores. Thank you.

John

Thanks John! I’m glad you found useful, and appreciate the comment.

I just bought my first *good* hatchet and was wondering about the notch! Thanks for maintaining this site, it’s a wonderful resource.