Do axes come sharp? (What you need to know)

I have bought a LOT of axes over the years, and the truth is not many are ready to go right from the factory.

Most axes do not come truly sharp. Many lower-cost axes come shaped to a point but don’t have a proper cutting edge. While others are roughly ground by hand and are inconsistent. Only premium axes tend to come properly sharpened.

Different companies will bring their axes to different levels of sharpness, through different methods – so price isn’t always an indicator.

I have a list of what to expect from most of the major brands further down.

Should an axe be sharp?

An axe should always be sharp. It makes the axe more efficient, and actually safer when used properly. A sharp axe will dig into the wood deeper, and be less likely to bounce or ricochet – which is how a lot of accidents happen.

So a chopping or felling axe should be very sharp, but a splitting axe doesn’t need the same level of attention.

There are some other considerations, and I have an article here on when you need a really sharp axe, and when you don’t.

Why most axes aren’t sharpened:

Axes typically don’t come properly sharpened to cut down on labor costs during production and to avoid potential legal issues

1. Sharpening adds time and cost

An axe head can be shaped consistently pretty well during production, but to truly sharpen the edge takes the time of a skilled worker. So not only does it take time to sharpen the axe, but it takes time for someone to learn how to sharpen them (and do it quickly).

Hults Bruk said that it takes 10x more time to sharpen a premium axe compared to a standard one.[1]

One exception to this is Fiskars – who make their axes a unique way. They have a machining process that leaves them with a decent chisel grind edge. They aren’t quite shaving sharp, but they are much better than you would expect for the price. Learn more about Fiskars axes here.

2. Sharp axes can be dangerous (duh)

Now more than ever – nobody wants to get sued. So an axe probably shouldn’t be sharp when it will just be left on a hardware store shelf, with only a rubber sleeve to make it “safe”. You need to avoid dumb customers and lawsuits.

What makes a good axe edge:

There are two parts to the effectiveness of an axe and “sharpness” is only one of them.

1. The cutting edge

Obviously, the actual edge of the axe needs to be sharp like a knife. This will cut through wood fibers while chopping, needing less force to drive deeper.

2. The profile of the blade

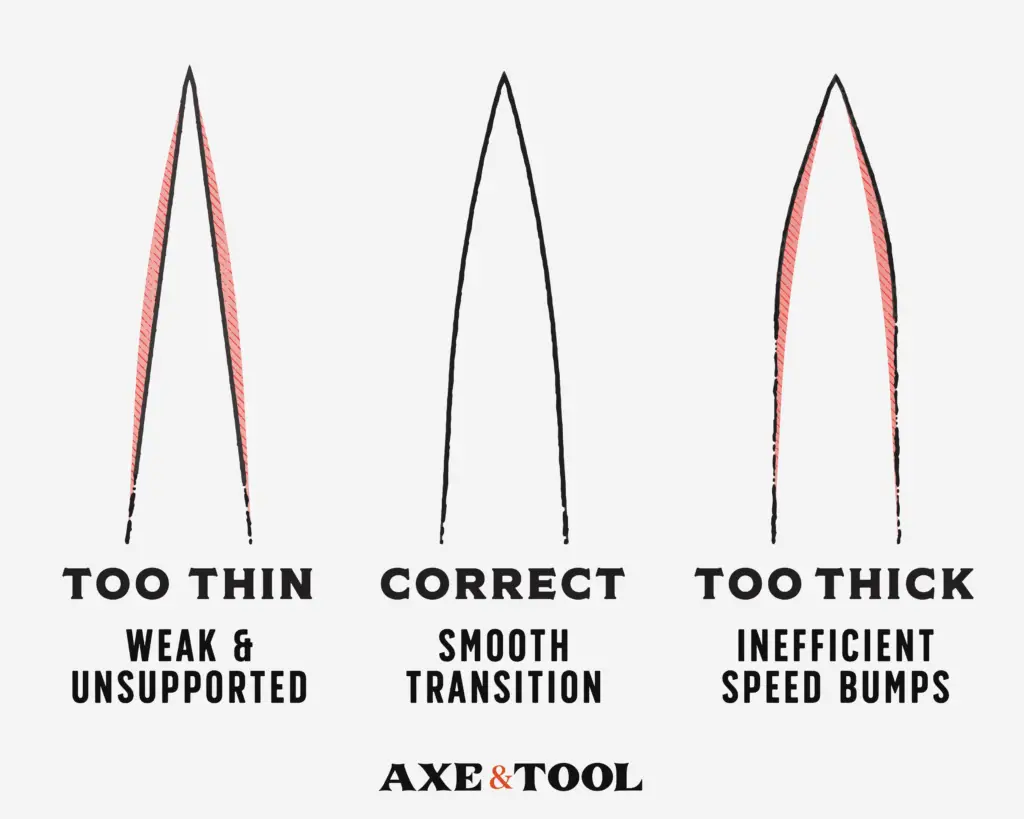

The shape of the blade right behind the edge can be as important to its performance as the edge itself.

Often on new axes the transition from the blade shape to the actual edge is fat and abrupt. This can act like speed bumps and cause drag as your axe passes through the wood.

This is usually what needs fixing on rough ground edges.

But unless you know what you want, try working with the axe a bit before you modify the profile.

Some axes like Fiskars have a flat grind edge and don’t have a curve shape at all.

What axes come sharp

Most axes CAN just be used straight from the factory – even if they don’t have a great edge. They will be workable, even if they aren’t perfect.

I’ve owned and used a lot of axes, and the level of sharpness from the factory can generally be categorized into one of three buckets:

| Sharp | This edge will cut. |

| Shaped not sharp | A consistent profile that comes machined to a point but needs sharpening to make it a true cutting edge. Can be sharpened with just a stone. |

| Rough grind | The edge can be sharpish, but a quick grind often leaves the bevel uneven. Likely needs a file and stone to bring to peak performance. |

Generic hardware store or Amazon brands are almost always in the “Shaped not sharp” group.

I have notes on how to sharpen further down.

| Brand | Sharpness |

|---|---|

| Adler | Good shape, sharpish |

| Agdor (Hults Bruk) | Rough grind edge, nice shape |

| Bahco | Good shape, not sharp |

| Brant and Cochran | Sharp |

| Council Tool (standard) | Great shape, sharpish |

| Council Tool Velvicut | Sharp |

| Council Tool Woodcraft | Sharp (flat grind) |

| Cold Steel | Good shape, not sharp |

| CRKT | Good shape, not sharp |

| Estwing | Great shape, not sharp |

| Fiskars | Sharpish (machined flat grind) |

| Gedore (Ochsenkopf) | Good shape, not sharp |

| Gerber Freescape (Fiskars) | Sharpish (machined flat grind) |

| Gransfors Bruks | Sharp |

| Helko | Sharp |

| Hults Bruk (premium) | Sharp |

| Hultafors (premium) | Sharp |

| Hultafors (standard) | Rough grind edge, nice shape |

| Husky | Good shape, not sharp |

| Husqvarna (Wood) | Rough grind edge, nice shape |

| Husqvarna (Composite) | Rough grind, heavy coating dulls the edge |

| Lexivon | Rough grind |

| Prandi | Good shape, sharpish |

| Schrade | Good shape, not sharp |

| Snow and Neally | Shaped not sharp |

| Stihl | Shaped not sharp |

More info on how to treat each of the three buckets is below.

What you will need to make your axe sharp:

There are many ways to sharpen an axe, but the best way is with a sharpening stone and axe file.

How your axe comes from the factory will depend on what you need to sharpen it properly.

1. Sharpening stone or puck

If an axe is shaped but not sharp it can be made sharp with just a sharpening stone. All you need to do is focus on turning the point into a true cutting edge.

A stone is also a key tool for maintaining a sharp edge as you use your axe.

Learning to use a stone or puck takes practice – so don’t expect to be a pro instantly. I found videos on YouTube helpful while I was learning. I will be writing a full guide soon.

You can get expensive sharpening stones, but you don’t need to break the bank on your first stone. I like the larger ones when possible because it’s easier to keep the edge consistent on a larger axe blade.

2. Axe file

You will need an axe file to smooth out the transitions and fix the blade profile for any rough round axe edge.

You simply clamp down the axe and smooth out the transitions with the file. Going back and forth to make sure both sides are even.

The file can also be used to set (or reset) a sharp edge, but you don’t want to just a file to sharpen each time as it will remove too much material and wear your axe down too quickly.

Axe files are also inexpensive, and a good tool to have for any axe, as chips and edge wear are inevitable.

Tip: A file card is handy to clean your file out – otherwise metal shards can get stuck and put gouges in your axe while you work (amazon).

Premium axes can often still be improved

Some experienced axe users like to thin the profile of their blades for really aggressive chopping, even on expensive premium axes. The profiles are still usually a little on the thick side for strength.

However, If you buy a premium axe do not go and immediately start messing with the edge. In fact, I don’t recommend anyone buy a premium axe for their first axe.

You need time to learn how to use it, how to sharpen it yourself, and what blade geometry you like. Don’t learn to sharpen on an expensive axe.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Really finding your articles helpful. You mentioned you were writing a axe sharpening guide. Has that been published yet?

Thanks so much!

Hey Igor, not yet – I’m finding it to be a tough one. It has been on the to-do list a long time, and I have started and stopped many times. I will try and get it done in August. Thanks for the poke.

Really good article. Just bought a smaller splitter (Estwing wood grain special edition). It arrived with a somewhat sharpend profile but not sharp enough for the oak we have. This article helped a ton. Thanks Jim!

Enjoy your Estwing, those limited edition models look SLICK. Glad you found the post useful, and thanks for the comment!