How To Remove An Axe Head (with pics)

There are a few tips and tricks I have learned over the years for getting axe heads off and old or damaged handles.

While it’s simple, it’s not always easy. Some of these old axe heads can be stubborn.

It’s easiest if you don’t care about saving the handle, but there are ways to get the head off so the handle can be reused (sometimes).

Removing an axe head to replace the handle

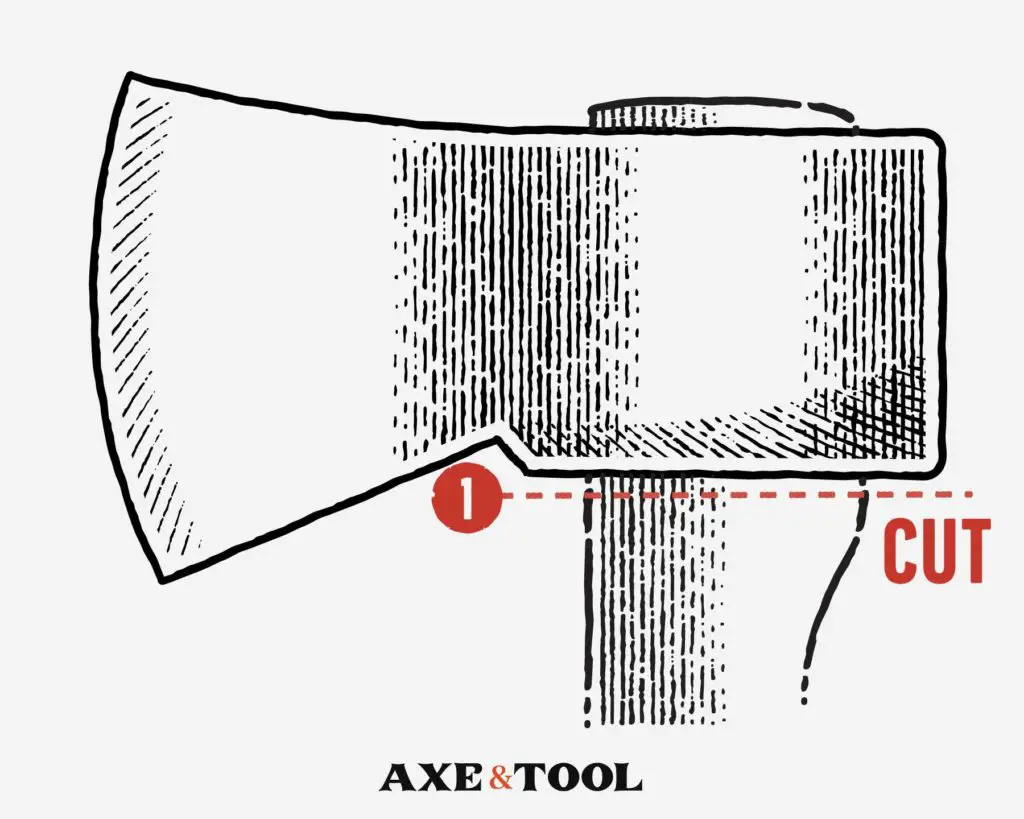

Step 1. Cut off the handle

First cut off the handle flush with the eye (or as close as you can).

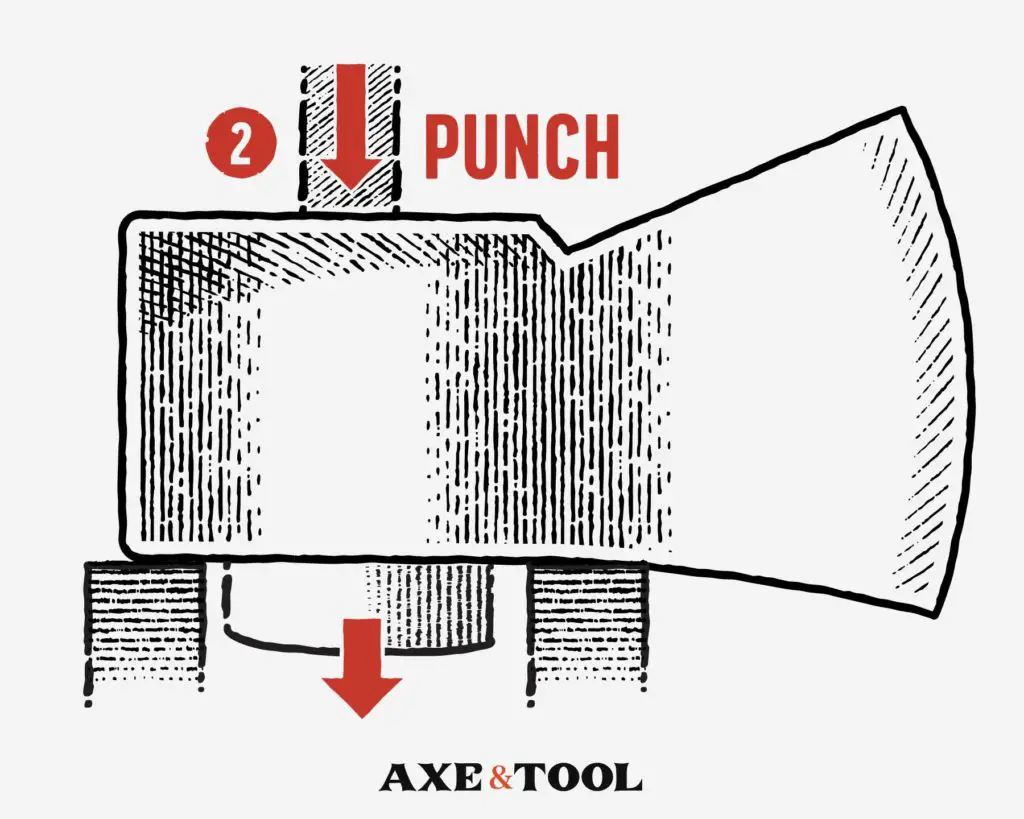

Step 2. Punch out the eye

Stand the head upside down between two pieces of wood so the top of the eye has a gap beneath it, or stick it in a vice (add wood blocks to avoid scratches).

Use a heavy punch and a hammer or mallet to knock the wood out of the eye. Make sure you are hammering it on the bottom side (that you cut), so it will pop out the top. The top of the eye will be wider than the bottom, so it will only work in one direction.

Step 3. Use a drill on stuck wood

If the wood is stuck tight (which it often is), use a drill to break it apart in the eye.

Sometimes the easiest method is to go straight for the drill. Especially if the wedge has been glued in place. Just drill and drill, hole after hole until the wood breaks apart and falls out.

Epoxy sealed axes

These can be a pain, and will likely need to be drilled out. But it’s the same process.

Metal wedges

Some axes will have metal wedges – not the cross wedges, but full metal wedges.

Some of the really old ones have a topper that can be pried up, but most of them are just crappy aluminum wedges, and they are a pain.

Again, just drill and hammer – but these are the most frustrating by far. The aluminum is softer than the axe head, so they really wedge in there and form to fit. But you can drill through them (especially at the skinny end).

Hopefully the methods above work for you, but if you are desperate, read on.

Removing very stubborn handles with Fire

Read carefully because this method can ruin an axe if done incorrectly.

There are sometimes handles that just wont budge. And years of oil and dirt can harden the hickory to the point where even drills wont make a dent. At this point I will usually try something like a chisel to break the eye apart. But if that doesn’t work… There is always fire.

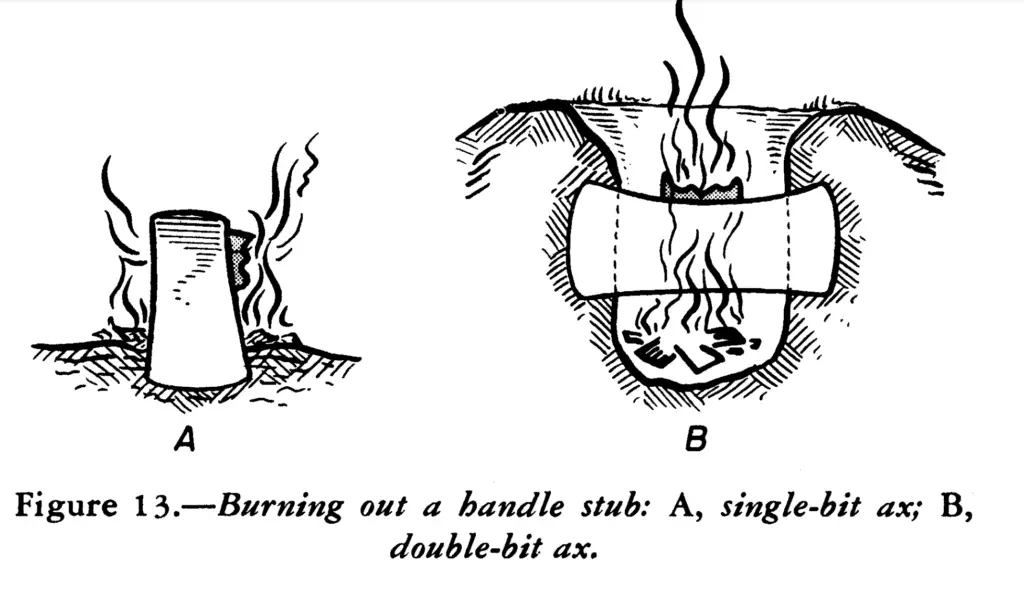

Image from the Loggers’ Handbook

This method is suggested in the USDA‘s Northeastern Loggers’ Handbook (Published 1951), but I DO NOT RECOMMEND IT.

You can burn the wood out of the eye, but you must be very careful with this approach. Heating up the axe head can ruin the temper on the blades and cause it to break or shatter.

Tempering metal is tricky, and if the blade gets too hot it will either soften and be unable to hold an edge, or become brittle and will shatter on impact.

The blade must stay cool

The Loggers’ Handbook suggests packing the blades it wet earth to keep the blade cool while the wood is burned out. I think you could use a wet towel in a vice as well – just keep adding water as you go.

Then try and keep the fire localized to the wood as much as possible.

Removing an axe head while saving the handle

Note: If there is a full metal wedge or epoxy seal, you likely can’t save the handle. You will destroy it before getting the wedge out.

Method 1: Deadblow only (if you are lucky)

If the head is loose already, you can sometimes just hold the axe upside down and smack it repeatedly with a dead blow hammer. Hit the blade side then the back (pole) back and forth until it pops out.

This may damage your hammer – so don’t do this method if you care about that.

If it doesn’t move much after the first few strikes I would move on to the next method. This is a great one when it works – but it won’t always.

Tip: If the head is valuable, don’t use a dead blow with a metal center, or you will risk scratching the head.

Method 2: Removing the wedge

If you want to try and save the handle to be rehung, you will need to get the wedge out so the handle can slide out the eye.

If the wedge has been glued you are out of luck.

First Remove the Cross Wedge

First, if there is a cross wedge, you will need to remove that before you get to the main wedge.

The best way is to use a chisel or maybe even a screwdriver to pry it up and out. It’s best if you can get a little notch in the skinny side of the wedge, and pry up (using the edge of the axe for leverage).

You may need to dig into the top of the handle a ¼ inch to get it out with pliers – so make sure that you have enough shoulder room on the handle to hang the head lower than it originally sat if needed.

Then Pull Out the Wedge with Screws

You need to remove the wedge if you want to re-use a handle. There is usually not enough shoulder below the head to just cut it off and re-hang it.

The best way I have found to get the wedge out is with screws. Screw 2-3 in along the top of the wedge, and use those to pry it out with pliers.

You may also need a vice here to get it out.

If screws aren’t working:

You may need to do some very delicate drilling if the screws aren’t working, or the wedge breaks. Break the wedge apart and pry it out, bit by bit.

Lastly, Hammer the head off the handle

With the wedge removed, you can use a mallet or dead-blow to hammer the head off the handle (holding it upside down).

It’s best to use a softer wood wedge (like poplar) when rehanging an axe on an old handle.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Great info, thanks. I am trying to get a 1960’s cut off handle out of a # 1/2 lb head. Using titanium bit and I can’t get a bite into the wedge.

The hickory is do hard around wedge that is start smoking and bit doesn’t go it at all. Dynamite?

Oof – yeah sometimes they can be a real pain. I have broken more than one bit old hickory. I haven’t tried dynamite… But I have had luck with a chisel. Just digging in enough to allow the drill bit to actually bite.

Hello Jim, Thanks for the great info. Have gone through many axes not to mention chain saws. Have had 3 cottages in Moskoka Ontario Canada You really helped me Thanks for your time Regards Peter

Thanks for the comment, glad you found it useful!