Complete Guide to Axe Wedges [Illustrated]

Using the right wedge is critical to properly hanging an axe. The size, shape, and wood type all play a role in how strong the hang will be.

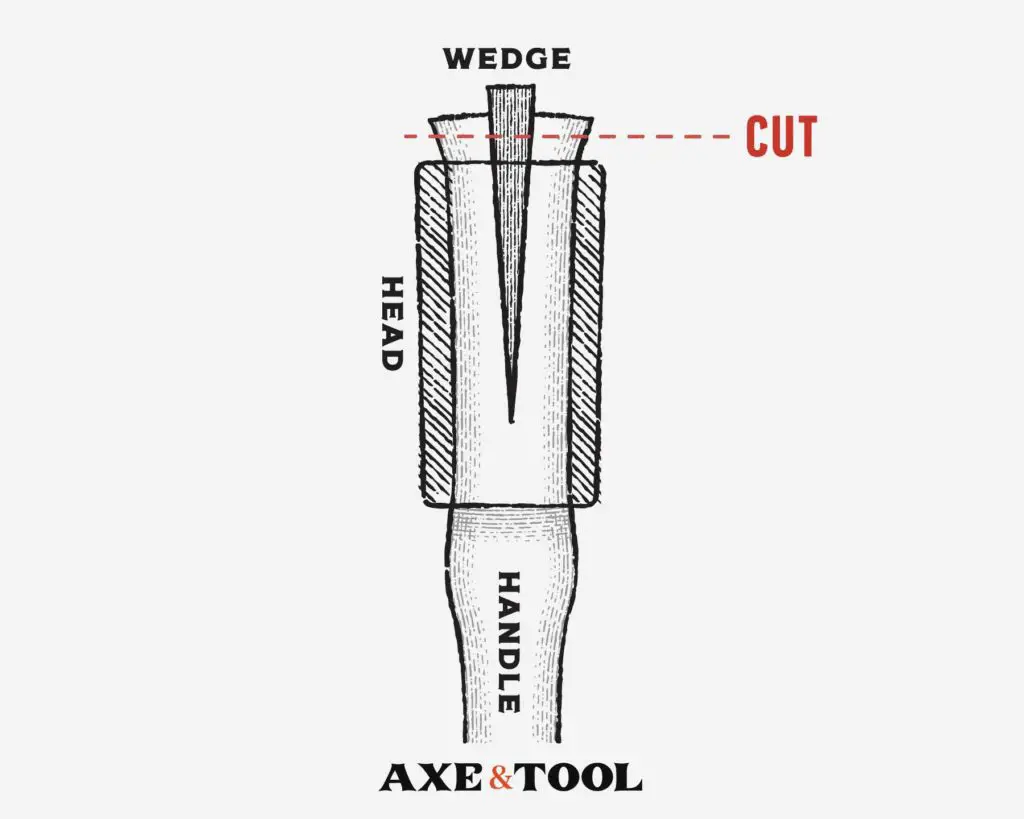

When assembling an axe, a wooden wedge is used to secure the head in place. Once the head is fitted to the handle, the wedge is hammered into a slot (kerf). This presses the handle tightly against the inside of the axe eye – securing it in place.

What size is an axe wedge?

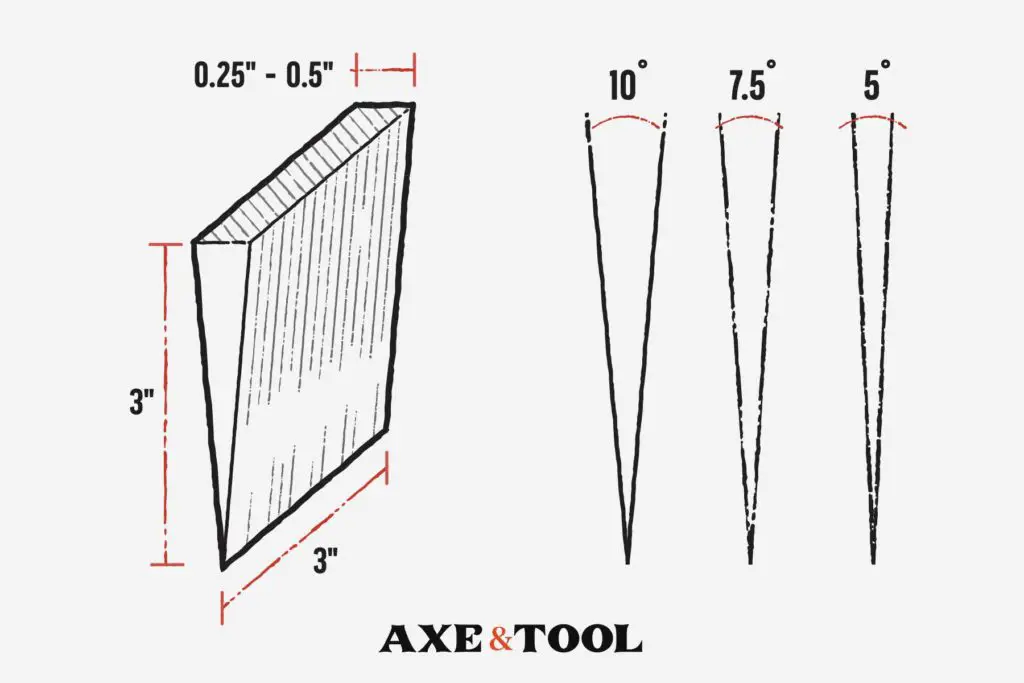

Axe wedges are usually made of soft hardwoods like poplar and start around 3” x 3” x 3/8”. However, the final size will depend on the shape of the eye and the wood type of the wedge. Wedges start larger than needed so they can be shaped, tapered, thinned to fit, and then cut down once hammered in.

No axe is the same and the way the handle fits in the eye will determine how thick and what shape your wedge needs to be. Smaller axes like hatchets will have shorter wedges, but the angles stay the same.

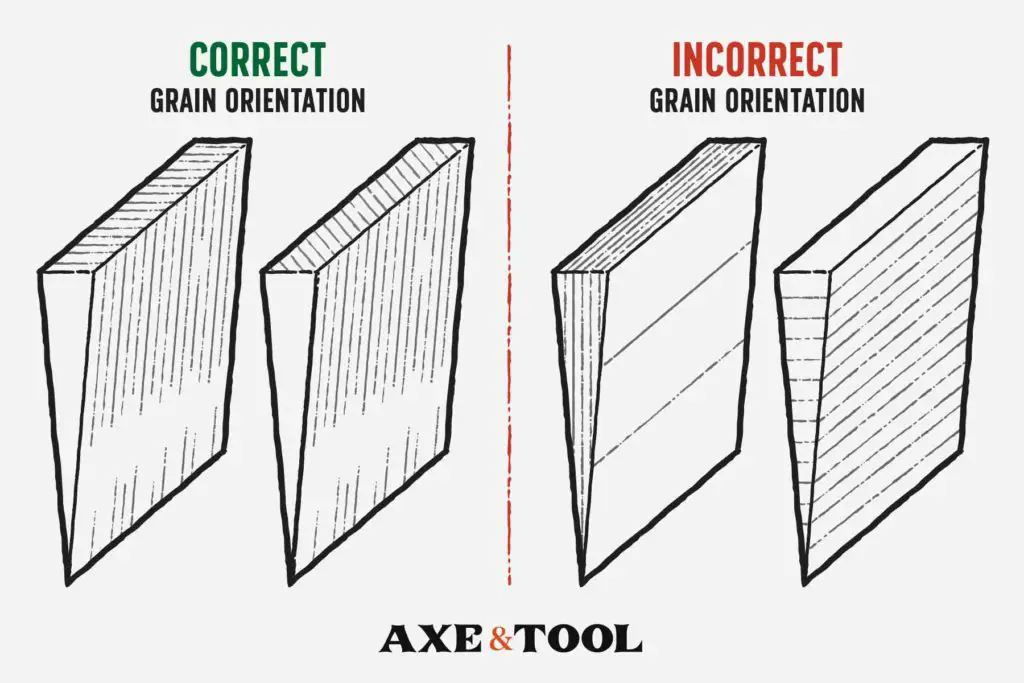

Does the grain orientation of the wedge matter?

The grain should run perpendicularly across the top of the wedge. Either straight across or at an angle.

This ensures wood in each grain segment is connected from the bottom point to the top spine, and will keep the wedge from weakening if it breaks apart when being hammered in (which happens).

If you use the incorrect orientation, pieces of the wedge can actually pop off when being hung.

If you get the basic orientation right, any other grain considerations will be negligible. Other minor factors could be:

- Straight grain will compress more consistently than curves

- Tighter grain will be more dense and compress a little less

But even to premium axe makes, typically only orientation matters. Some axes I have clearly have wedges that were cut from near the center of the tree where wide grain runs in dramatic curves, and I have never had an issue.

So just try and get the orientation right, and don’t worry too much about the rest.

What angle are axe wedges?

Wooden axe wedges are typically cut between 7.5° – 10° but can go as low as 5°. For a standard 3” wedge, the spine width would be between 0.5″ (10°) and 0.25″ (5°). The eye size and wood type can impact the final width needed.

Even if the wedge is not exactly 3″, those measurements are a pretty safe guide. Here are the exact measurements below:

| 5° | 7.5° | 10° | |

| 2.75″ | 0.24″ | 0.36″ | 0.48″ |

| 3″ | 0.26″ | 0.39″ | 0.52″ |

| 3.25″ | 0.28″ | 0.42″ | 0.57″ |

When deciding the thickness – mentally add up any gaps around the top of the eye with the kerf, and then make sure the wedge is a bit wider. Remember that the wedge is taller than it needs to be – so you will be looking about an inch below the top of the wedge.

You will also need to consider how much the wood in the wedge will compress – so keep reading to learn more about wood types.

The wedge should go all (or most of) the way down in the slot in the handle (kerf), so draw a line on your wedge to mark the depth for comparison. Then you can tell how far down it is when hammering it in. You won’t always get it all the way down – but that’s the goal.

Fatter wedges are standard and are better for softer woods that compress but can be thinned as needed. If a wedge is too fat, it may not go in far enough for a strong hold, or it can actually start working itself out as you use the axe.

Harder wood wedges tend to be thinner as the wood won’t compress as much. I still typically start them thicker so I can thin as needed and shape them a little more for the specific axe.

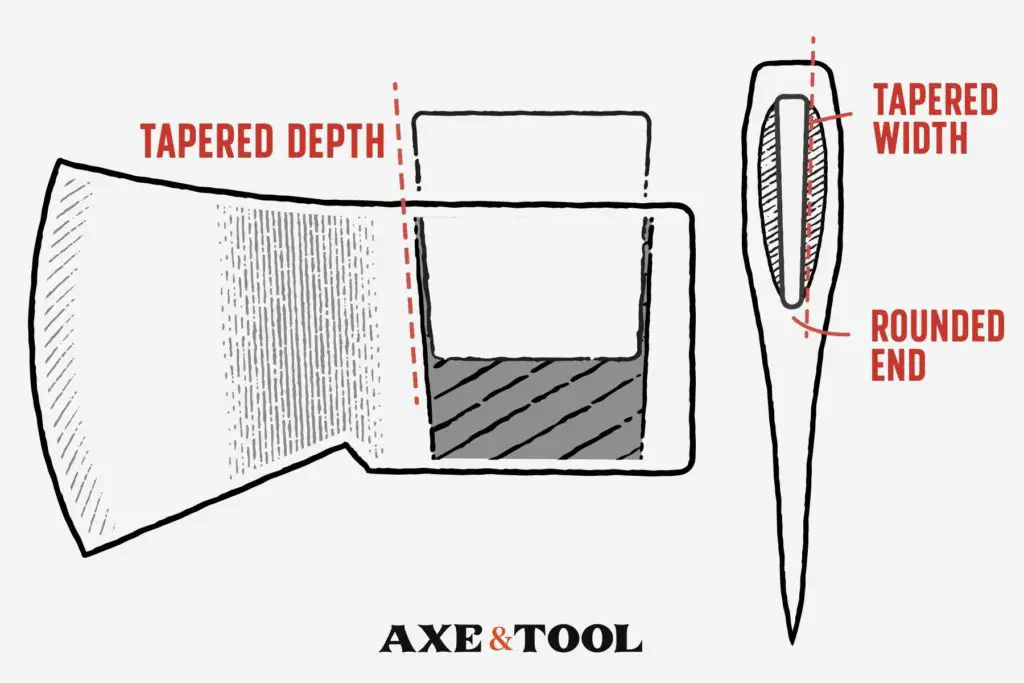

You may need to shape the wedge

The axe eye will be wider at the top than the bottom, and variations can occur during the forging process. So while wedges start square, they may need to be tapered and shaped to properly fill the eye. A 3×3 wedge will be longer and taller than is needed so you have enough wood to shape and work with.

TIP: The easiest way to thin a wedge is with a belt sander.

Hardwood or Softwood for axe wedges?

Axe wedges are made from hardwoods. Commonly soft hardwoods like Poplar are used because they compress, making them easier to fit. Harder woods like oak, walnut, and cherry offer unique colors and more durability but require more skill to fit properly, and should only be used in new handles.

The truth is almost any wood can work in a pinch. But the characteristics of the wood will dictate how you need to shape and fit your wedges. So you don’t need to find a specific type of wood, BUT you should know what you are working with.

Softwoods (from conifer trees that stay evergreen) will work, but won’t hold up as well as hardwood. They grow quickly and are less dense. The pressure from being wedged in the axe head can crush and compress fibers over time, causing the wedge to shrink. This will cause the axe head to loosen.

Hardwoods are best for axe wedges because deciduous trees (trees that lose their leaves annually) tend to grow slower, producing harder and denser wood. Density is important for wedges because they need to hold their shape under constant pressure to keep the axe head tight on the handle.

Using a soft (hardwood) wedge

When you get an axe handle kit from the hardware store, it’s probably going to come with a soft poplar wedge. This has become the industry standard. It will easily compress and conform to the shape of the kerf (the cut) and eye, filling any gaps without much shaping. This makes softer wood a great choice for beginners or a quick repair.

Only soft wedges should be used when rehanging an older axe on its original handle. Older handles that have already been somewhat shaped by the previous wedge will be more brittle and might split if a hard wedge is used.

Soft wedges are not as “pretty” as the harder options and they are more likely to crack and split when you are hammering them in. It’s totally fine for the wedge to crack, just hammer in each piece as far as it will go. It shouldn’t affect the strength of the hang, just hammer it all in.

Using a hard wedge

Hard wedges will last longer than a conventional soft wedge but need to be shaped more accurately to the space.

Hard wedges need more consideration and shaping than soft wedges since they won’t conform as much to the space around them. They also need to be a little closer in thickness to the space as they won’t compress as much either.

If your wedge is harder than your handle (like a hickory wedge in an ash handle) – it’s likely going to compress the handle wood first (which is fine).

Popular woods for axe wedges:

| Species | Hardness | Trait |

| Poplar | Soft | Industry-standard, easy to use, paler in color than hickory |

| Cherry | Soft | Heartwood has a pink tone, stands out |

| Elm | Soft | Deeper brown and a nice subtle contrast to most handles |

| Beech | Medium | light color, straight grain, and easy to work with |

| Black Walnut | Medium | Dark pop against hickory or ash. The heartwood has the deepest color. |

| Maple | Hard | Bright color and takes stain well |

| White Oak | Hard | Durable and paler in color, somewhat porous |

| Ash | Hard | Similar look to hickory |

| Hickory | Very hard | Match your handle, or use darker heartwood |

| Osage Orange | Very hard | Super durable and turns more orange with time |

Can I use pine for an axe wedge?

Pine will work for a short-term axe wedge, but the soft fibers will compress and loosen over time.

I have bought used axes with Pine wedges that may have worked for a while, but the wedges ended up deteriorating and the heads were very loose.

Woods to avoid for axe wedges

| Species | Hardness | Trait |

| Cedar | Varies | There are many types of Cedar, and their characteristics vary greatly, so I would just avoid it unless you know what you have. |

| Red Oak | Hard | Porous open grain will break down and compress over time. |

| Paduk | Hard | Porous open grain will break down and compress over time. |

Glue my axe wedge?

This is a matter of opinion – and there are some pros and cons.

Most people glue their wedges, it will be stronger and lower the chance of your axe head loosening, or the wedge backing out.

I tend not to glue my wedges, because I want to be able to remove them if the head comes loose (and I want to know if I mess up a hang). If you glue your wedge will never be able to re-use the handle. So I typically just load it up with boiled linseed oil to help it swell and stick.

I have a detailed article with pictures on how to oil your axe, with some tips for the best finish.

BUT – if you aren’t worried about that and just want to make sure the head can’t come off, even if it loosens then carpenters glue is a good solution. just rub a little onto either side of the wedge right before you hammer it in.

Where to buy axe wedges

If you don’t want to make your wedges:

Hardware stores will generally have wedge kits that come with a large Poplar wedge, and metal cross wedge for about $5. But there are sources online that offer a wide range of wood types and bulk orders as well.

Whiskey River Trading Co. has a great selection of axe wedges in different types of wood for a very good price. They are also known for their excellent range of handles. See their selection here.

Thrane Axe & Saw Co. has a ton of options and awesome customer service (Maryland). They also sell handle blanks if you want to carve your own. See their options here.

Beever Tooth Handle Co doesn’t offer the same range of wood types, but you can’t beat the price. Hard hickory wedges are sold by the dozen or half dozen here.

You can always get a standard wedge kit from Amazon as well, which comes with barrel wedges rather than the standard straight step wedges (for some variety).

Why are some wedges metal?

You have always been able to get steel or aluminum wedges to use instead of wood (full wedges – not the stepped cross wedge).

They aren’t too popular anymore, but they can create a lot of pressure, and be installed easily. There will usually be gaps at the front and back, but the metal can compress the handle wood and force its way in.

Metal wedges are a huge pain in the ass to remove if you need to swap out a handle.

Some of the vintage ones are kinda cool – they have a cap on top that also makes them easier to pull out. But I won’t use or re-use a metal wedge.

Adding metal cross wedges

Finally, you will often find a metal step wedge or barrel wedge hammered across the middle of the wooden wedge. This is done to create even more pressure and secure the head. However, there are some things you should know:

Traditionally a cross wedge should not be added when hanging an axe, the wood wedge should be secure enough. The cross wedge (or barrel wedge) should only be added if the head starts to loosen.

I still sometimes add the wedge when hanging, if I suspect a weak spot or maybe just not the best hang. But if you are learning it makes sense to leave it out and test the strength of your hang before adding anything like a cross wedge or glue.

I typically use a #3 step wedge for full-size axe eyes (1/2″ or 15/32″ wide). But there are larger or smaller as needed.

If you go to the hardware store you will likely only find kits that also include a wooden wedge, but you can buy bulk packs for cheap on Amazon (like this one).

This is just a hobby, but if you buy through a link I may get a commission that supports the site. Thanks!

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Great article! Also agree on Thrane, they are truly good people and have amazing customer service (and high quality blanks). I started (as you mentioned) gluing my wedges. But I’m trying to refine my skills in shaping the eye and wedge so that I can, with confidence, set the hang with BLO.

It’s a journey.

Thanks for the comment – and it sure is a journey. I just had to pull out a wedge from a bad hang (of mine) yesterday. It was looking “instagram ready”, until I felt the tiniest little wiggle. I was livid, lol.

Great article . I just hung my first hatchet, and am really enjoying all the axe knowledge .

I use Swel-lock with the wedge, it is recommended by the USFS and secures the wedge but makes repairs easier

Great information, Thank you for such quality instructions.

Hi Jim! Your website is brilliant. The content is very well detailed and comprehensive, one can learn lots of things about axes. Thank you for the good info!

Thanks, appreciate the comment!

If your good with a 110 mig welder I can put a nail in a car body dent puller that normally has a screw for pulling dents . I put my welding ground on the dent puller hold the nail center of the wedge . Put a small tack weld on both side of the nail connecting it to the wedge two ways and two times let the thing hang down with the dent puller holding it up right and what ever the wedge is in hanging down under it. Then just take the slide and slide it up as fast as you can about three or four good wops if your weld holds it will jerk the wegdge right out I just beak the wedge free holding it with pliers I regrind it and use it again . If the cleets are not sharpe or feel like they don’t wanna bite I just use a little triangle file to cut some of the edges of those cleets sharp so they will grab and hold them in the wood . There’s nothing more dangerous than a tree falling on you other than a flying axe head or a 8-10-or 12 pound sledge hammer . I make sure I wedge good if it be comes lose knock the handle up tight use a chisel if it’s a straight wedge . If it’s the safety kind then a 1/4 drive cheap socket you just have to size them up we’re they match up and the socket will tighten the wedges up then they should be below the service . I just cut the wood sticking up straight off with the top . As far as getting the out another way is to take a torch burn the wood on both ends several times not getting the head orange , red , or yellow after the second time the wood will just smolder in the head just let it smolder if it will for a half hour or so . Put some just room temp water on it cool it off and try beating it out from the bottom side with a punch or chisel . Most of the time they will come out with a little burning or drill holes down from the top down so you don’t drill your wedges . When it comes out you can collect your wedges then . But if you weld them out then that handle will come off so easy because most of the time when they come out the wooden wedge will fall out or come out when the metal ones do ! I’ve takin handles off one head and use them on another two or three times . People say it can’t be done I can show you I’ve did it by welding to the metal wedge and pulling them out like weeds out of the garden !

Hi, great article on wedges! I got three axe books for Christmas and none of them went into this kind of detail. Although I did know most of this here. My question is if you have any experience with douglas fir as a wedge, and what are your thoughts on it? I have been using it frequently, my reasoning being that a) I have lots of clear fir here in BC and b) it is medium hardness and slow growing. I know that softer hardwoods are the go-to, but my theory is that “harder” softwoods should be about the same in density, strength etc. Or at least comparable. I am happy with the axes I have used it on so far, but it’s only been a couple years and I don’t want trouble down the road especially as I sell some axes also. I am using them mostly on new Hickory handles that I make and I try to fit them well. Interested to hear your thoughts.

I’ve never tried fir but your rational makes complete sense. It’s non-porous and fairly straight grain – so I suspect you won’t have an issue. But please let me know if any issues do creep up. I may have to give it a go myself if I come across any. Glad you found the post useful, and thanks for the insightful comment.

Thanks for the informative article. I have a question, I bought a replacement handle from Handle House and I have some open space towards the axe blade. I have seated the axe and it looks good. Should I fill that area in with epoxy? From the fit I think it going to work fine but would like your read on it. Thanks David

A little space can be okay, but it depends on where the space is. The bottom should be tight all around (or very close). A little gap at the top isn’t uncommon. I wouldn’t epoxy, it will just be a pain later. But you could try adding another little wood shim in there to fill the space, and then add a metal cross wedge somewhere in the eye to tighten everything up (if you haven’t already).

The easiest way to tell though is give it a few swings and see if anything moves… If you are still unsure and want to send me a picture, my email is on the about page.