6 Ways To Tell The Top Of An Axe Head

It can be tricky at first to tell which way an axe head is supposed to go. I have seen a lot of axes installed upside down.

But don’t worry – there are 6 easy ways to tell which side of the axe head is the top. You can usually tell from the first one or two tips alone.

The most accurate way to tell the top of an axe head is to examine the eye. The hole in the top of the head will be slightly larger than the bottom of the head. It can be hard to verify without measuring, so other clues like brand marks and nail pullers can help.

TIP: If you are not immediately hanging the head on a handle – use a pencil, marker, or tape and draw an arrow on the axe head before putting it down. Save yourself the hassle in the future.

1. Logos and Labels are Typically on the Left Side

Logos, words, and labels are almost always on the left side of the head. They are almost always stamped (or stuck) on the axe heads so the start of the word or numbers is at the top side of the axe.

This is not a 100% guarantee – there are oddball axes out there that do it differently. I know German Ruhr axes tend to have the brand on the right side, and sometimes there is stamping on both sides.

But the vast majority have the brand mark is on the left side, especially in the US.

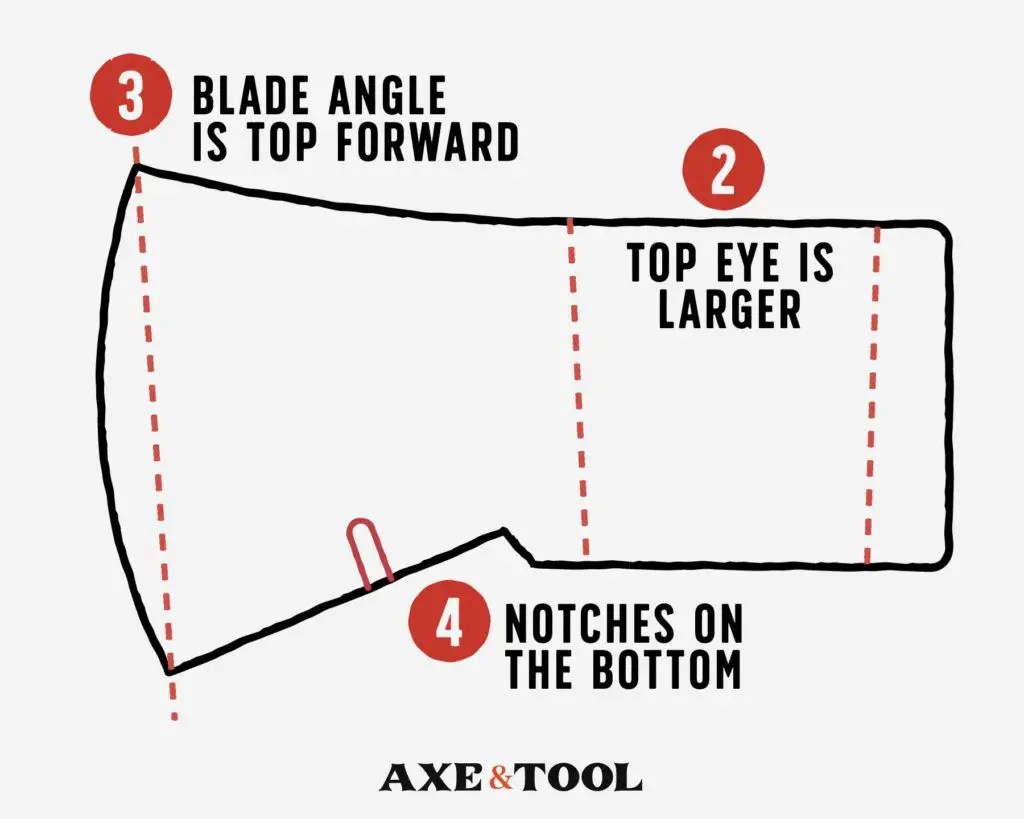

2. The Top of the Eye is Larger

You can tell the top of an axe head by measuring the eye (the hole in the axe head). While both sides will often look identical, the opening on the top side of the axe should be a little wider or longer.

When hanging the head on a handle, extra room is needed for adding the wedge to lock the head in place. The smaller hole on the bottom ensures the (now) wider top can’t slip back through.

This is the most sure-fire way of telling the top from the bottom of good quality or vintage axes.

Cheap, newly made axe heads may have eyes that are too close to tell, or that are identical.

3. Examine the blade angle

A slight angle in the blade is common. The top corner (toe) is often further forward than the bottom corner (heel). The bottom will only ever stick further out on very worn axes.

This one can be hard to tell if the axe has been well used and crudely sharpened (many times), and the blade has been well worn (see point 6).

This angle should only ever be inwards from top to bottom, as it can add a mechanical advantage when chopping. This inward angle is often referred to as being angled “closed”.

Some axes have a straight perpendicular blade, and older well-worn blades may be misshapen due to years of sharpening.

But an “open” angle, with the bottom more pronounced, will only ever be found on specialty tools like carving axes.

4. Notches Are on the Bottom

Notches on the axe head are found on the bottom side of the axe head.

There are 3 common “notches” found on axe heads that all show up on the bottom side of the axe:

- Nail-pulling slots can be found in the blades of various hatchets.

- V-shaped notches between the blade and the eye of the axe redistribute the force of impact reducing the strain on the handle.

- Large U-shaped gaps under the blade allow for the user to choke up on the axe and get better detail control (see previous image above).

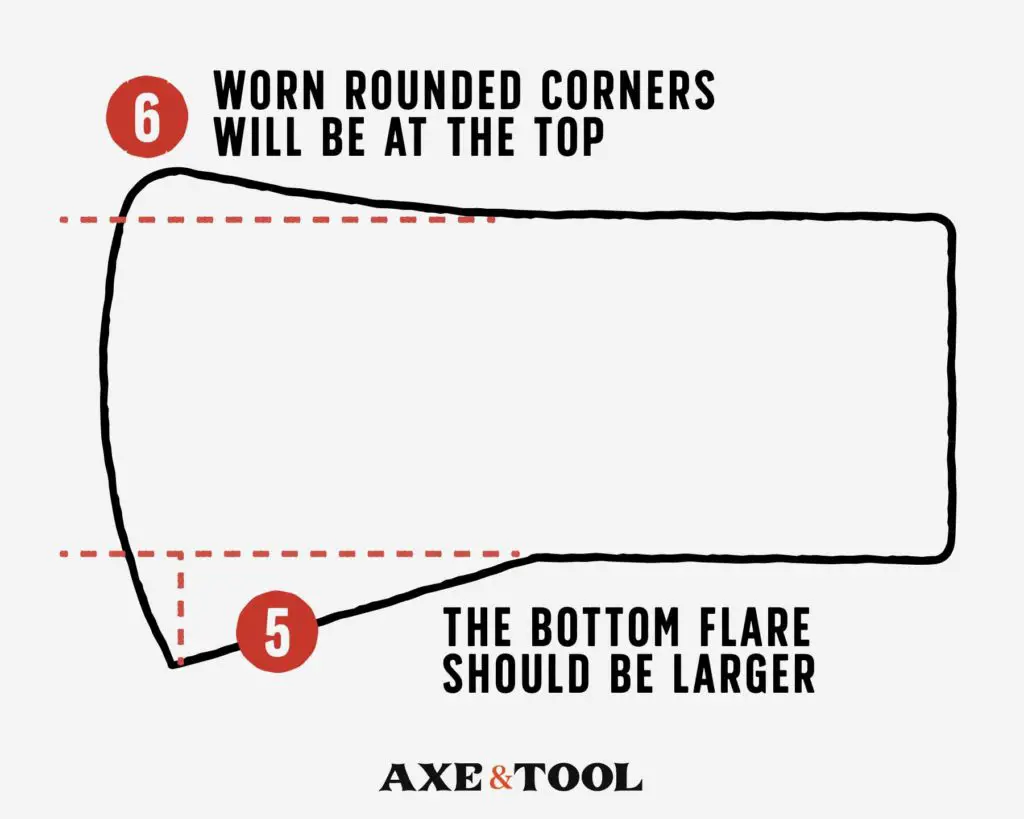

5. The Bottom Corner Flares Out

You can generally tell the top of an axe head by the flare of the blade. The bottom corner will flare out more than the top, looking like a horn if the axe is upside down.

While they can look symmetrical at glace, simply rotate the axe head a few times and it will become apparent which end of the blade extends out further.

This is especially easy with most American patterns, as the tops tend to be much flatter.

The top corner (toe) of the axe needs to be flatter to work when chopping on the ground, and performing tasks like bucking. Otherwise, it would dig into the dirt and get chipped.

Restoring an axe? Check out my article on the nuances between the different kinds of curved axe bits.

6. A Worn Rounded Corner

A rounded corner on one corner of an axe blade (bit), is almost certainly the top (toe). This comes from regular resharpening fixing chips from accidentally digging into the ground and dulling or chipping on rocks.

That corner gets pulled back more than the rest of the blade each time it gets damaged or resharpened. This can throw off the angle from point 3 but is generally a good indicator of the top.

Please comment below If I missed something or if you have any questions. I do my best to respond to everyone.

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Thanks enjoyed the article as an amateur axe collector an restorer my self, big fan of double bit Collins axes it was informative on a few points I didn’t know, I have a couple double bit axe heads I’d be curious on your opinion on.

So far I have really only spent a lot of time with single bits – I have a couple double-bit heads, but haven’t touched them yet. It’s on the to-do list, because I know it’s currently a bit of a gap in my knowledge.

I have an ax with 5 holes along the top the head is square with a grill pattern to it. It also has a notch for nails or maybe barbed wire. No stamp or mark. Head is 7 inches long . Looks like it was made for checking up near the top with your hand. The holes seem to be made when the ax head was made. Definitely a blacksmith made. Have any ideas on the 5 holes? Thanks, Victoria Simpson

Sounds like it cook be a roofers hatchet, maybe? They have a thin square blade with holes for measuring shingle depth, nail pullers, and often had grill patterned hammer on the back. But I may not be picturing it right. Feel free to send a pic (my email is on the about page), and I would be happy to take a look.

Hi! Great article! I was hoping you could help me. I have an axe head that weighs 7.8 pounds. It’s 8″ long. On, what I am assuming, per your article, is the bottom of the axe, there are 4 stamps. Two above the eye, two below. The top one is the letter M in a circle. The 2nd one is possibly the letter B in an oval ( or it’s a skull wearing glasses in it’s side 🙂!). The third says US09 and the last one is a number 8 over a crescent moon shape in a circle. If I could post a picture of it, it would probably make more sense! Anything you can tell me would be greatly appreciated. I found it on William’s Mountain in Seth, WV.

Thank you in advance for your time!

Hey, Janet – this feels like a shot in the dark, but based on the description – look up “Woodings Verona Maul” on google and see if any pictures match what you found. If not, feel free to send me pics (my email is on the about page), and I will happily take a look.

Hi, thank you for your assertive and informative articles. A cut above the usual one can find online these days 🙂

I’ve got a 4 pound head unhandled, which I refurbished. I’m ready to fit it to a handle I’m making myself (also with help from other articles of yours)… what’s driving me nuts is that the toe flares more than the heel!

I almost stubbornly fitted it the other way around, but there’s no doubt: the eye hole is smaller on the side with less flare. Also, the head has only one mark: a 4 stamped on the same side as the smaller side of the eye.

I’ve got another two axes and both have their weight stamped on the same spot (facing you when you hold the axe)

The blade angle is kinda neutral, slightly closed, and the toe doesn’t seem to have been overly worn. The total size (and weight) suggests not much material has been lost.

Have ever seen an axe like this, flaring “upside down”? It looks completely wrong.

Cheers Jim, keep on swinging!

Paulo

Hey Paulo,

a couple possible reasons come to mind.

1. Most likely, it was just a poorly made axe. Even good axe companies had lemons, especially earlier on where they were made by hand. A worker could have easily punched the eye the wrong way. While some companies would scrap these duds, some workers would take them home or they could pass through unnoticed.

2. Different regions had their own unique patterns (including South America) – I’m not as familiar with patterns outside of Canada/USA, but I know I have seen Italian and german axe designs with a highly flared toe. Look up “Biber Axes”.

Feel free to email pics if you like, my email is on the about page.

Thank you for your views. Agreed, seems like a mistake in the making of it – I’ve found a few more oddities on the inside of the eye. I’ll send you a photo just for curiosity.

I’m pondering about my next step: I’ll reshape the eye and/or handle it based on what feels/looks more natural. I reckon if I fit it darn well it won’t slip …none will know what’s going on inside.

Cheers