What Makes a Good Axe Handle & What to Look For

These days there are lots of cheaply made axe handles in hardware stores. Some will still be great handles (or at least have potential), while others should be completely avoided.

So you need to make sure you examine what you are getting, to avoid the duds.

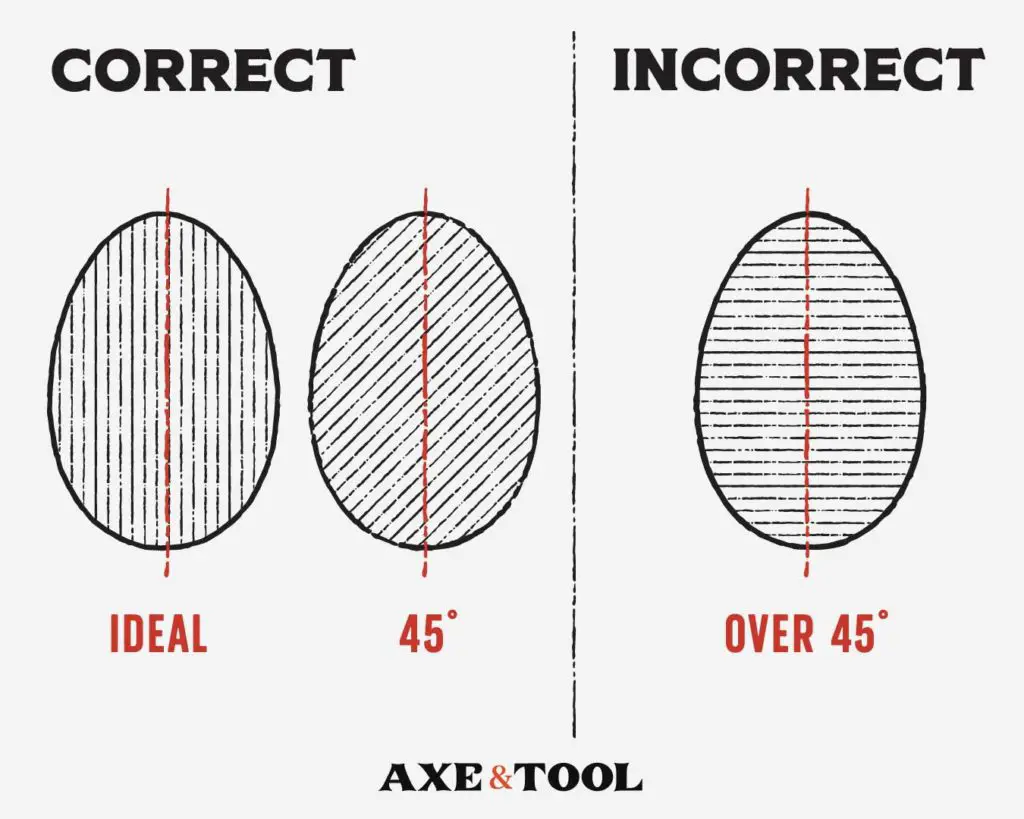

1. Grain Orientation in Axe Handles

The best way to check grain orientation is by looking at the bottom of the handle.

The grain in an axe handle should be fairly straight, running parallel with the direction of the axe. This will reduce the chance of the handle breaking as it flexes in use. Angled grain up to 45° off-center is considered “acceptable”.

This is considered a best practice but can be an overblown issue – especially for short handles. Gabriel Brånby (previous owner of Gränsfors Bruk), and custom axe maker Hoffman Blacksmithing both state it doesn’t matter for handles under 24″.[4,5].

Check for cracks at the bottom

When you are looking at the orientation of the grain, also look around the palm swell for signs of cracks. It’s not uncommon for a dry handle to crack if dropped – which can spread up, jeopardizing the handle. This is one reason it’s important to oil your handles once installed.

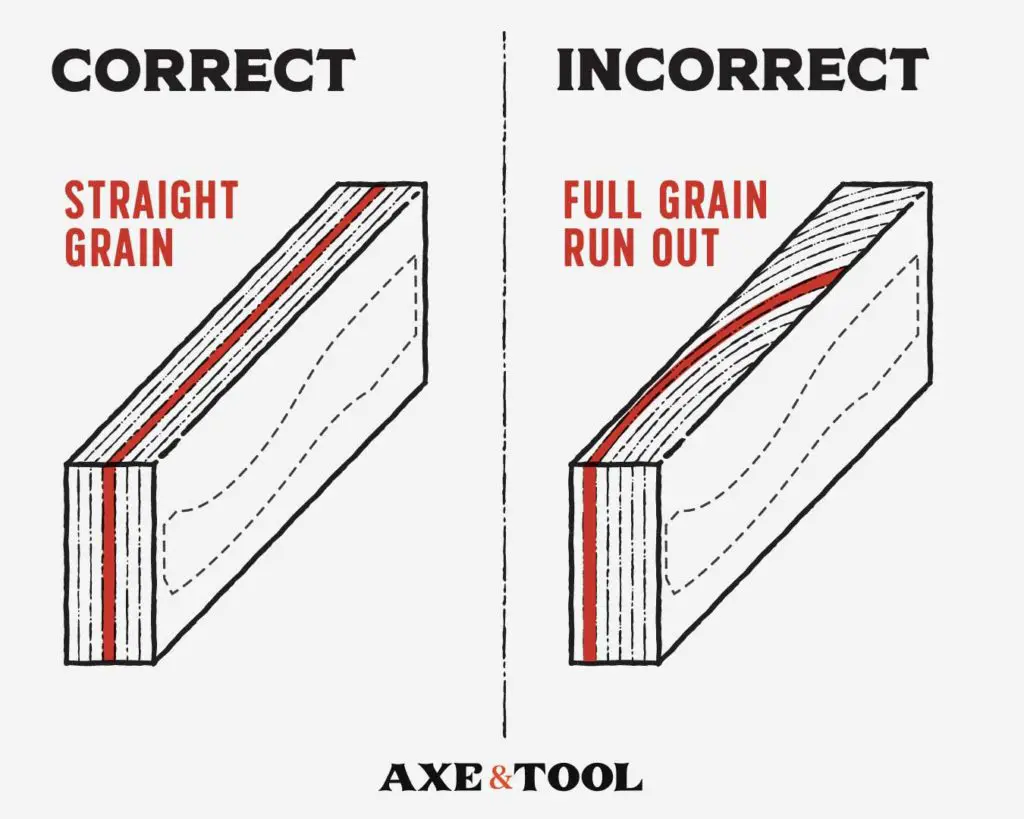

2. Grain Runout is More Important

No matter how straight the grain looks at the end of the handle, the whole thing will be compromised if there is a lot of grain runout.

Grain runout is when the grain curves or is angled, running out the side of the handle rather than continuing straight through from top to bottom. Grain runout creates a weak point in a handle, that can crack or break when used.

Some runout is fine (and unavoidable), but you do not want the grain to cut across the width of the handle. I have found handles that have such dramatic runout, that not a single grain of the wood runs the entire length of the handle.

You can spot a lot of run-out easily if you see heavy “feathering” or what looks like a waterfall happening along the sides of a handle.

3. Sapwood vs Heartwood Doesn’t Matter

While axe handles will almost always be hickory, you may find some that are darker (heartwood), some that are lighter (sapwood), and some that are a mix. This will not affect the strength or performance of the handle and is purely cosmetic.

Sapwood is from the lighter outer rings of the tree, while Heartwood is from the darker core. The USDA did 2 studies in 1936 and 1966 on the differences between sapwood and heartwood and determined there is no meaningful difference.[1]

4. Avoid Knots in an Axe Handle

Knots weaken an axe handle by interrupting the flex when used – becoming a breaking point.

A knot at the end of the handle grip can be forgiven, as that area of the handle doesn’t flex, bend, or take an impact – but a knot anywhere else should be avoided.

Pinhole Knots are Acceptable

While they don’t always look nice – a few small pinhole knots or dark “streaks” can be excused, even if they are in the middle – they won’t harm a handle too much.

5. Check the Size of the Eye

The first step is to make sure the handle will fit your axe. The handle eye should be slightly larger than the hole in the axe head so it can be shaped to fit. Most handles these days will have large American eyes, but there are smaller ones.

Many of the handles from Swedish makers have smaller eyes.

6. Check the Kerf

The kerf is the slot cut in the eye of the axe handle. Most handles come with a pre-cut kerf, but make sure it’s near the middle of the eye, and fairly straight.

The kerf doesn’t have to be perfectly straight or dead center – but the closer the better. An offset kerf will cause the handle to be weaker on the thinner side.

7. Varnish Should be Expected

If possible, get a handle without varnish – although most hardware store handles come varnished these days.

The varnish will keep the handle clean on the shelf, but is hard on your hands during use and prevents the handle from being oiled – which is essential for long-term maintenance.

I have articles on how to remove varnish and properly oil your handle.

8. Fat and Poorly Shaped Handles

Handles you find in the hardware store will come thick, and maybe poorly shaped. Some of the worst handles can vary wildly in shape. So take a quick look to see if they are consistent, and use extreme scrutiny if they aren’t.

A fat handle isn’t a big problem – it’s easy to thin and shape a handle yourself. A thin handle gives better control and causes less fatigue. See how I do it for all my handles: how to thin a handle.

You can buy better handles than you can find in a hardware store if you know where to look: Where to Find Good Axe Handles

9. Straight vs Curved Handles

This is a matter of preference, but there are some common applications for both.

Typically if you are using an axe just for splitting wood, you want it to have a straight handle. The straight handle rotates less and is more consistent for landing repeated even strikes. This also makes straight handles better for carpenter’s axes and hatchets.

Curved handles are more ergonomic for chopping, bucking, and felling trees – where the bent handle will allow the axe to reach further.

I have a full article on curved vs straight handles with more information.

10. Choosing a Handle Length

This will also be a preference, but choosing the handle length is directly connected to your work. Longer handles provide more power – while shorter handles are portable and nimble to use.

This is a bit simplified, but here is a rough breakdown of the standard axe sizes. Most handles you find in a hardware store will be 36″, 28″, or for a hatchet.

| Axe Type | Length | Head Weight |

|---|---|---|

| Full-sizes | 30-36″ | 3-5lbs |

| Boy’s Axes | 24″-28″ | 2-3lbs |

| Small Axes | 18-23″ | 1.5-2.5lbs |

| Hatchets | 13-17″ | 1-2lbs |

If I missed something or you have any questions, feel free to leave me a comment below. I do my best to respond to everyone.

Resources

[1] – USDA – Strength And Related Properties Of Woods Grown In The United States (1935)

[2] – Bushcraft USA – 183764, Summary of USDA Testing

[3] – Bushcraft USA – 184377

[4] – Canadian Outdoor Equipment Company, Question to Gabriel Brånby

[5] – Hoffman Blacksmithing Premium Axe Handles

About the author:

About the author:

Jim Bell | Site Creator

I’m just a guy who likes axes. I got tired of only finding crap websites, so I set out to build a better one myself.

I’m also on Instagram: @axeandtool

Great source of all around information on the axe as a tool and how to maintain it. I have a few tricks that I use in my building and maintaining, but we seem to have the same views and beliefs in a lot of your writings. This site is my go to now and looking forward to reading new facts and how-to’s in the near future. Thanks for the knowledge.

Appreciate the comment – thanks!

Thanks for the comprehensive article. I’m about to build a large “Paul Bunyan-sized” double bit axe and your articles here are proving to be quite helpful! Thank you!

Awesome! Great project (and something everyone needs), glad to hear the site has been useful. Appreciate the comment.

Thanks Jim. I have two boy axe heads and two broad axe heads that were my Dad’s. I have two sons. Your article is exactly what I needed before heading to the hardwood yard to select Hickory for the handles and restore these tools to usable condition for my sons.

Glad you found it useful, sounds like an excellent project to keep those tools in the family. I’ve got a hatchet of my grandfathers I’m planning to restore for my son (when he’s older). Thanks for the comment!